Educators and tech leaders look back on 2016; predict where edtech trends in teaching and learning will head this new year. With every new year comes new ideas. To get a glimpse into what the next 12 months will hold for everything from professional development to digital learning, and from communication to virtual reality, 15 ed tech luminaries looked back on 2016 edtech trends to help predict what’s in store for 2017. Here’s what they said: At Moss, we partner with Boxlight to provide affordable solutions for:If you are looking to keep up with the latest ed-tech trends, we can customize a solution affordable on almost every education budget. You tell us - what solutions you are looking to implement in your classrooms in 2017? How can we help? 15 hot edtech trends for 2017 adapted from eSchool News online publication.

0 Comments

Universal Laser Systems is known for quality, versatility and reliability. Investing in a premier, cutting edge laser cutting and engraving system is only half the battle - maintaining is a necessary component to ensure your laser is able to provide optimal performance. A robust maintenance program is a huge step toward that objective. Rest assured - maintenance doesn't have to be expensive to be effective. Our partners at Universal Laser Systems has set out to provide a DIY guide to maintaning your laser's performance with a series of tips and suggestions written by their expert support team to help you keep your laser system in tip-top shape. Since fine-tuning is often the key to obtaining the best quality, we want to be sure you have a mixture of the most up-to-date information and fine-tuning suggestions cultivated by our team through collective years of experience. Check out the first installment in this series, which pertains to maintaining optics. Have a question for the ULS service team? Send them to Moss and you may be featured in an upcoming edition! The Great Debate – Additive vs. Subtractive Manufacturing (What Your Students Need to Know!)12/1/2016 Experts are discussing an important shift in manufacturing technology: which is more beneficial, additive or subtractive manufacturing. Let's face it - it's a crowded field, full of technologies and applications. Fictiv discusses the future of production in this blog post, and how people are choosing technology for tomorrow’s industry. In today’s maker-climate, each technology has advantages, and implications for your students.

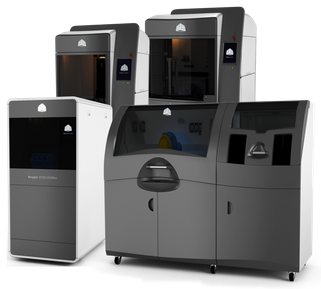

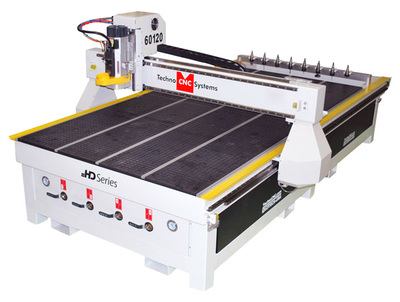

Additive Manufacturing Additive manufacturing is another term for 3D printing, and can use a variety of materials and printers. 3D printing has always been very useful for rapid prototype development, but it is starting to make its impact on the manufacturing world as well. Materials such as PLA and ABS plastics, as well as composite and metal materials improve printing. 3D printing is used as a step in the design process in companies ranging from Nike to Ford. Designers will print a prototype and use a 3D rendering to test and develop and enhance in a way that drawings can’t duplicate. Prints are faster and cheaper to produce than traditional machine tooling. The precise dimensions (often printed in color) provide a realistic model for designers and engineers to manipulate. Subtractive Manufacturing Subtractive manufacturing is a process by which 3D objects are constructed by successively cutting material away from a solid block of material. Subtractive manufacturing can be done by manually cutting the material but is most typically done with a CNC Machine. One of the advantages of subtractive manufacturing is the variety of materials that can be used, from wood and metal to plastics and acrylics to plasma. (Finer applications such as laser engravers work with an even wider array of materials.) CNC is widely used in manufacturing, and can be found in most facilities. Necessary Skill Set There is ongoing conversation about which method is more prevalent in the future of manufacturing. In reality, both have a place in 21st century manufacturing, which is why your students should be familiar with both technologies. In order for someone to comfortably use either technology, they need a solid understanding of design and CAD (Computer Aided Drafting) programs, as well as a familiarity with engineering principles so they can understand and develop using the best materials for the project. CNC operators should have a mechanical aptitude, and be able to read blueprints and drawings. Learn More You can give students hands on experience with both additive manufacturing (3D printing) and subtractive manufacturing (CNC). Moss partners with the following companies to provide cost-effective classroom solutions:

Afinia is always looking to improve the user experience for educators, which is why they asked for your feedback, and incorporated your suggestions into the new and improved H800+. The updated 3D printer includes:

Award-Winning InnovationThe Afinia H800+ 3D printer won the RAPID 2015 Exhibitor Innovation Award, which recognizes the most innovative new products or services exhibited at RAPID that are judged to have the greatest potential impact on the industry. Afinia 3D was selected as the recipient by the Society of Manufacturing Engineers’ (SME) Rapid Technologies & Additive Manufacturing (RTAM) Committee. TechZone 360 also chose the Afinia H800+ 3D Printer for their 2015 3D Printing Excellence Award, citing Afinia 3D as a leader within the 3D printing industry. The TechZone 360 3D Printing Excellence Award identifies products, services, and applications that are driving the growth and evolution of 3D Printing from niche market hype to mainstream reality. Learn More This printer boasts the largest print surface for large-format designs, and superior print resolution to similar 3D printers on the market. Download an updated spec sheet, or contact Moss for more information. Weigh in: will these improvements make a difference in your classroom? How will you incorporate this updated technology? Is your school seeking to attract non-traditional students to STEM-related welding and manufacturing technology programs? Are you struggling to direct students to a skilled trades career path? Here’s a report from The Morning Journal about a recent Careers in STEM event at Lorain County Community College for area high school students presented by the college’s chapter of the Society of Women Engineers. The college used a Lincoln Electric VRTEX® virtual reality welding simulator to engage students and let them try their hand at SMAW welding. LEARN MORE.

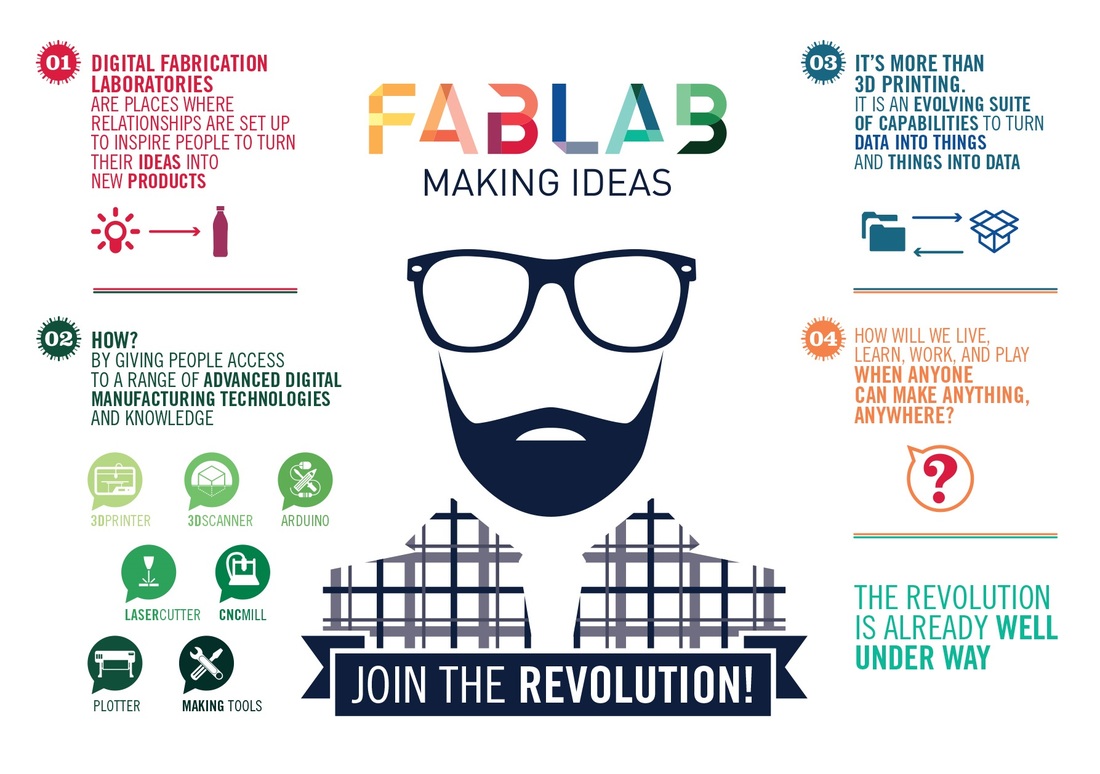

Students choose career paths for a variety of reasons. Gender norms are playing less of a factor as students are exposed to technologies (and potential career paths) earlier. What are you doing to encourage students to pursue studies (and careers) in Industrial Technology? We'd love to hear your tips in the comments section! Does your design and engineering program have a Fab Lab? If not, your students may be missing some key opportunities. Fab Labs are popping up in colleges and technical centers, offering tools and technology enabling students to create and refine. A Fab Lab, short for Fabrication Lab, is ideal for students to design and create prototypes, and is filled with tools designed to enable students through the design process. Fab Labs are most popular in schools with strong engineering and design progams.

While each Fab Lab is different, they have similar components. If you are designing a Fab Lab, consider implementing these elements:

Fab Labs can complement in-class instruction, and provide a “lab” environment for coursework. We want to hear from you – are you considering adding a Fab Lab? What tools are you looking for to complete (or begin) your Fab Lab design? Let’s talk about management systems for a moment. Classroom management is one of the crucial, key components of success in a Pitsco lab. If you’ve taught using Pitsco, you have likely seen the migration from Colleague to Synergy. Now, there is a migration under way to ITC.

ITC stands for “In The Cloud”, or a cloud-based management package. This technology makes the teacher more nimble, and gives back more control of the classroom instruction. We’ve compiled a list of the top benefits of using this classroom management system:

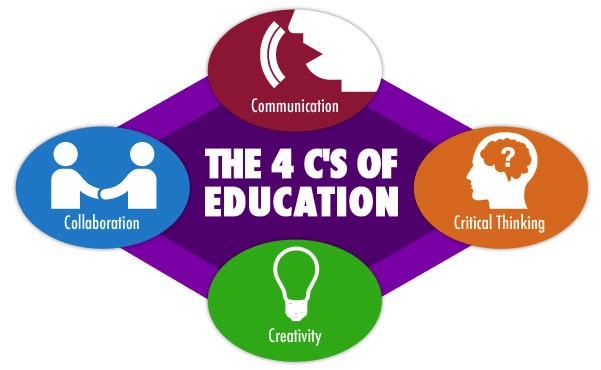

Students can monitor and manage their learning experience. Synergy ITC allows each student to log on – individually or with his or her partner – to complete assigned Expeditions, activities, and assessments. Students learn through hands-on, multimodal, collaborative activities while navigating through a digital Expedition at their own pace. Each benefit amounts to one thing – more teacher control and more customization, which equals a better experience for both student and teacher. Did you know? Pitsco adds an average of 10 features each month to ITC, based on user feedback. If you have a question or a suggestion, you can share via phone, email or live chat. Have you used ITC management from Pitsco? Let us know what you think (and how we can help make your experience unforgettable!) We hear a lot about how important it is for today’s students to develop 21st century skills, in addition to ‘the basics.' The 4 C's (Communication, Collaboration, Critical Thinking, and Creativity) are often described as the ‘new basics.’ Learn how 3D design and printing can help students develop these vital new basics on Makers Empire's blog.

We want to hear from you -- do you use 3D printing in your classroom? How is it helping you teach the 4 C's of Education?  Our Troubled World Requires a Skilled STEM Workforce Elements of STEM are integral to our nation’s economy – from health care to infrastructure needs, energy, and the environment. That’s why one of the most important tasks we have as educators is to encourage our students to consider careers in STEM. To get them to that point, they need to develop the ability to question and plan ways through experimentation to find viable solutions. Do I Have a Dynamite Class Lesson? Have you ever asked yourself, “Do I have a class lesson that I could sell tickets for?” In other words, a lesson that students will absorb and remember, and that will leave them excited to take the next step? A lesson that does that probably includes more than just abstract theory or memorization of concepts. It probably also challenges the students with “out-of-the-box” thinking (aka critical thinking) through self or team experimentation – which is a lot more interesting and engaging than listening to a teacher lecture or demonstrate a science concept. As long as students are learning, you can use any means possible to turn on the “light bulb.” There is no more important gift than teaching students how science works through application and experimentation. Continue Reading... Blog adapted from Boxlight blog, with our partnership. Check out their full suit of solutions here.

|

AuthorYou have questions about STEM education? You're not alone! We're here to share ideas and provide thought-provoking commentary. Let us know your thoughts! Sign Up for Email Updates For Email Marketing you can trust. Categories

All

Archives

February 2017

|

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Training Equipment

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Training Equipment

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

RSS Feed

RSS Feed