If you have been in the market for a large-platform 3D printer, we have exciting news! Moss now partners with 3D Platform, a leading manufacturer of large-scale, industrial-class 3D printers. 3DP’s flagship 3D printer, the 3DP1000, offers a large build area of 1 meter x 1 meter x 0.5 meter. (To put this in perspective, this is more than 70 times the size of the average desktop 3D printer!) 3D Platform is committed to building on industrial strength linear motion components, actuators, and motors while maintaining affordable flexibility with open market software and control solutions. They offer helpful How-To training, videos, and FAQ on their website. Learn more - contact Moss today to learn about the most reliable, large format 3D printer in its class:

2 Comments

The Great Debate – Additive vs. Subtractive Manufacturing (What Your Students Need to Know!)12/1/2016 Experts are discussing an important shift in manufacturing technology: which is more beneficial, additive or subtractive manufacturing. Let's face it - it's a crowded field, full of technologies and applications. Fictiv discusses the future of production in this blog post, and how people are choosing technology for tomorrow’s industry. In today’s maker-climate, each technology has advantages, and implications for your students.

Additive Manufacturing Additive manufacturing is another term for 3D printing, and can use a variety of materials and printers. 3D printing has always been very useful for rapid prototype development, but it is starting to make its impact on the manufacturing world as well. Materials such as PLA and ABS plastics, as well as composite and metal materials improve printing. 3D printing is used as a step in the design process in companies ranging from Nike to Ford. Designers will print a prototype and use a 3D rendering to test and develop and enhance in a way that drawings can’t duplicate. Prints are faster and cheaper to produce than traditional machine tooling. The precise dimensions (often printed in color) provide a realistic model for designers and engineers to manipulate. Subtractive Manufacturing Subtractive manufacturing is a process by which 3D objects are constructed by successively cutting material away from a solid block of material. Subtractive manufacturing can be done by manually cutting the material but is most typically done with a CNC Machine. One of the advantages of subtractive manufacturing is the variety of materials that can be used, from wood and metal to plastics and acrylics to plasma. (Finer applications such as laser engravers work with an even wider array of materials.) CNC is widely used in manufacturing, and can be found in most facilities. Necessary Skill Set There is ongoing conversation about which method is more prevalent in the future of manufacturing. In reality, both have a place in 21st century manufacturing, which is why your students should be familiar with both technologies. In order for someone to comfortably use either technology, they need a solid understanding of design and CAD (Computer Aided Drafting) programs, as well as a familiarity with engineering principles so they can understand and develop using the best materials for the project. CNC operators should have a mechanical aptitude, and be able to read blueprints and drawings. Learn More You can give students hands on experience with both additive manufacturing (3D printing) and subtractive manufacturing (CNC). Moss partners with the following companies to provide cost-effective classroom solutions:

Afinia is always looking to improve the user experience for educators, which is why they asked for your feedback, and incorporated your suggestions into the new and improved H800+. The updated 3D printer includes:

Award-Winning InnovationThe Afinia H800+ 3D printer won the RAPID 2015 Exhibitor Innovation Award, which recognizes the most innovative new products or services exhibited at RAPID that are judged to have the greatest potential impact on the industry. Afinia 3D was selected as the recipient by the Society of Manufacturing Engineers’ (SME) Rapid Technologies & Additive Manufacturing (RTAM) Committee. TechZone 360 also chose the Afinia H800+ 3D Printer for their 2015 3D Printing Excellence Award, citing Afinia 3D as a leader within the 3D printing industry. The TechZone 360 3D Printing Excellence Award identifies products, services, and applications that are driving the growth and evolution of 3D Printing from niche market hype to mainstream reality. Learn More This printer boasts the largest print surface for large-format designs, and superior print resolution to similar 3D printers on the market. Download an updated spec sheet, or contact Moss for more information. Weigh in: will these improvements make a difference in your classroom? How will you incorporate this updated technology? Are you looking for ideas on how to integrate 3D printing into your existing STEM curriculum? You're not alone! Project-based learning and 3D printing are pivotal avenues for teaching STEM subjects, engaging students on new levels, and preparing them for future careers. Afinia offers several 3D Printing STEM Kits, which support project-based learning in the classroom.

Each pack comes with student workbooks and a teacher’s guide to help you seamlessly integrate the projects into your curriculum. Available STEM Kits include:

Integrating 3D printing into existing STEM programs is easy with these project-based units. Learn more - download this informational file today, or contact your Education Specialist for more information. We hear a lot about how important it is for today’s students to develop 21st century skills, in addition to ‘the basics.' The 4 C's (Communication, Collaboration, Critical Thinking, and Creativity) are often described as the ‘new basics.’ Learn how 3D design and printing can help students develop these vital new basics on Makers Empire's blog.

We want to hear from you -- do you use 3D printing in your classroom? How is it helping you teach the 4 C's of Education?  We are excited to announce that we now offer NinjaTek Cheetah™ flexible filament. This industrial-grade filament is the perfect blend of speed and strength: it is the fastest and easiest-to-use flexible filament on the market, and has an impact strength that is 84% greater than ABS. The filament works well in the Afinia H-series 3D Printers and is available in orange, green, blue, red, semi-transparent, white, and black. Want to learn more about the most cost-effective flex filament on the market today from Afinia? Contact one of our Education Specialists to learn more. Despite their tuxedoed appearance, penguins aren’t always well mannered. In the aftermath of one particular penguin scuffle among endangered African Penguins at Mystic Aquarium, Yellow/Purple (AKA “Purps”) was found to have a nonfunctional flexor tendon in her ankle. Much like an injury to a person’s Achilles heel, damage to a penguin’s flexor tendon leads to pain and difficulty in motion. Once Purps’ injury was identified, the veterinary staff at Mystic Aquarium took action with a handmade boot to immobilize, protect and support the damaged foot. Yet the animal care team knew more modern solutions were available that would not only be more durable and less cumbersome for the small bird, but also require less time than handcrafting the boot. Mystic Aquarium’s Chief Clinical Veterinarian, Dr. Jen Flower, proposed 3D printing. Blog courtesy of 3D Systems.

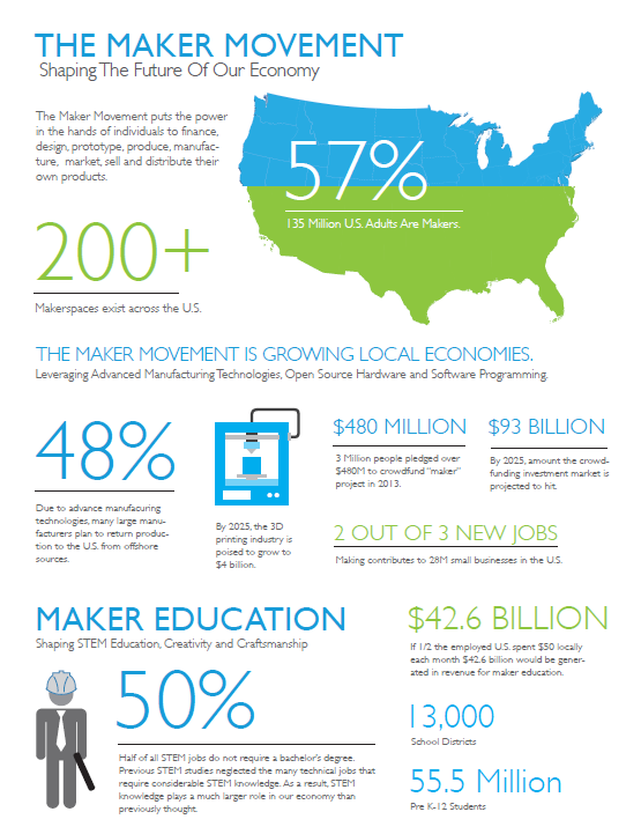

We've been hearing a lot about the Maker Movement recently. But what is the Maker Movement? Adweek hits it on the head: The maker movement, as we know, is the umbrella term for independent inventors, designers and tinkerers. A convergence of computer hackers and traditional artisans, the niche is established enough to have its own magazine, Make, as well as hands-on Maker Faires that are catnip for DIYers who used to toil in solitude. Makers tap into an American admiration for self-reliance and combine that with open-source learning, contemporary design and powerful personal technology like 3-D printers. The creations, born in cluttered local workshops and bedroom offices, stir the imaginations of consumers numbed by generic, mass-produced, made-in–China merchandise. In other words, the Maker Movement is home to the do-ers, the inventors, the designers of our generation. The people who use creativity to create and do.

Makers benefit from a space that has the tools to spur their creativity - whether it's a Fab Lab or a Makerspace - this space is designed to give people the tools to "figure it out." Most are filled with the tools of the trade, from 3D printers, lasers, robotics, and more. These people are looking for efficiencies, and driving creators and manufacturers forward with new innovation. Have you developed or used a Makerspace? What makes a successful Makerspace? Share your tips in the comments section. |

AuthorYou have questions about STEM education? You're not alone! We're here to share ideas and provide thought-provoking commentary. Let us know your thoughts! Sign Up for Email Updates For Email Marketing you can trust. Categories

All

Archives

February 2017

|

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Training Equipment

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Training Equipment

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

RSS Feed

RSS Feed