rWorkers today are called on to be subject matter experts in what they do. Gone are the days when someone can clock in and do a repetitive skill for hours. Today's workforce demands more: the same worker must now know how to assess, troubleshoot, fix, and communicate in a much more global sense. Work is less silo-ed, more interconnected with other teams. Added requirements are making it difficult for employees to stay ahead of demands, creating a skills gap. How do you train employees for these enhanced skill requirements? Many are turning to Registered Apprenticeships to fill the void. According to Why Apprenticeships are Taking Off, registered apprenticeships, not to be confused with less formal or company-specific apprentice programs, have five defining features:

Apprenticeships allow employers to hire and train workers with the necessary skills, while students can avoid an unnecessary financial burden of student loans. According to the Department of Labor, 87 percent of apprentices are employed after completing apprenticeship programs, with an average starting salary above $50,000. Registered Apprenticeship programs make a lot of sense in both urban and rural settings, and are easier to implement and facilitate than you may realize. In fact, the U.S. Department of Labor offers several registered Apprenticeship programs, backed by curriculum from leaders in education, like Amatrol. Looking to learn more, or get started today? Contact Moss for learning opportunities.

0 Comments

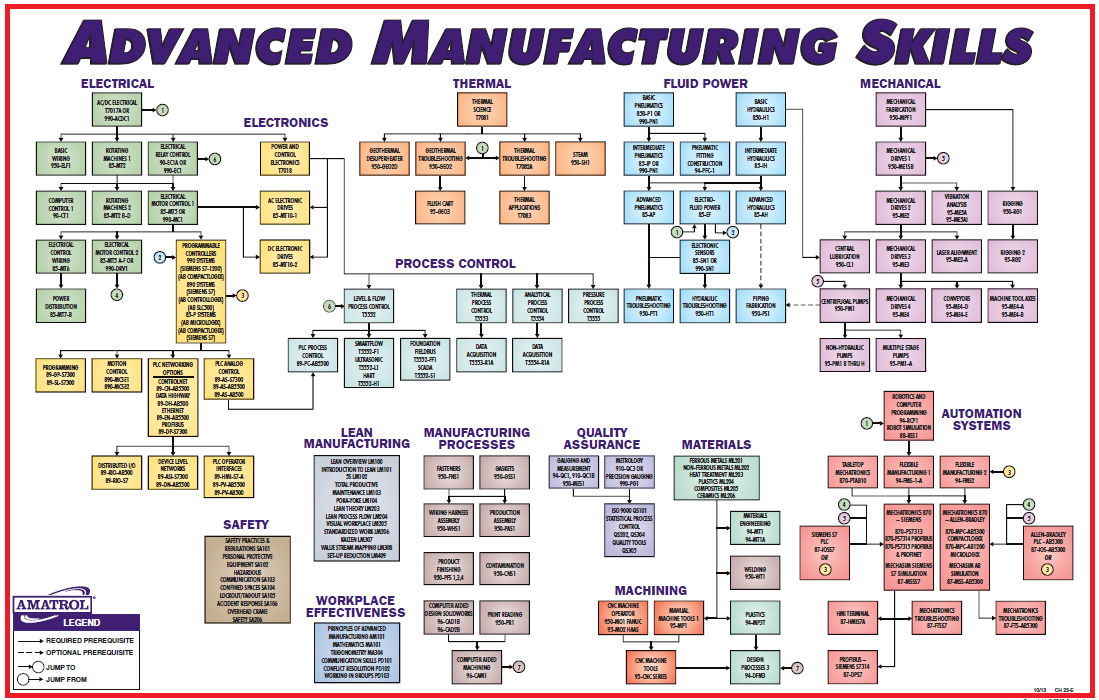

Moss is proud to offer equipment and curriculum from Amatrol’s Advanced Manufacturing program. Amatrol’s industry leading equipment and curriculum is developed in partnership with industry to deliver job ready, industry relevant skills. Working closely with companies like Caterpillar, Tropicana and many others Amatrol has designed equipment for work place success.

Key Features

Want to ensure you are covering your bases and addressing the skills training most needed in your region? Check out the skills chart, which aligns coursework to job-ready skills:  Amatrol has released its instructor training course schedule for 2017! The Amatrol Technical Training Institute (ATTI) in Jeffersonville, Indiana, provides courses on the technical subject matter and implementation of Amatrol Learning Systems. This training is a valuable opportunity for instructors to improve their knowledge base, and understand new training developments. Interested instructors will want to reserve their seat early! Please see the schedule for dates and times and enroll now to secure your place as these classes fill up fast!  ITC: Building the Workforce of Tomorrow Today's economy requires workforce members to possess a range of technical skills that can be used in team-based environments, so current students must develop both specialized hands-on skills and essential workplace skills like problem solving, teamwork and effective communication. Amatrol's Integrated Technology Concepts (ITC) program offers technical skills training across a wide range of real-world areas through project-based learning while interweaving essential workplace skills through team-based projects. This combination of skills and knowledge will put students on a path toward exciting career opportunities in areas like supply chain, automated distribution, engineering, medical, and more. Strong STEM Integration Facilitates College Credit, Industrial Certification Prep In addition to essential workplace skills, ITC emphasizes STEM skills. Combining STEM skills with hands-on applications helps to meld theory and practice in student's mind, which will assist them in knowledge retention and building skills for more advanced concepts. This STEM integration allows for many schools to establish transferable college credit hours for ITC courses. Amatrol's ITC proram is also a strong foundation in preparation for several industrial certification. Amatrol partners with organizations including NIMS, MSSC, ITEEA, and more for certifications like MSSC's Certifiied Production Technician and NIMS' Industrial Technology Maintenance certifications. Foundational Systems for Successful Careers The first step of ITC is Amatrol's Enterprise Systems courses, which provides the framework for integrating multiple technical skills successfully using teamwork. Students begin by exploring different technology sectors before studying team concepts, product design, business presentations, internet research, and much more. ITC Quick Facts

Want to learn more about this (or any other Industrial Technology program from Amatrol)? Contact Moss for an in-depth look today.  A recently published article in Manufacturing Business Technology, " Next-Generation Manufacturing: Are You Ready?" addresses the changing face of manufacturing facilities. These cutting-edge facilities embrace information-based approaches to manufacturing, advanced technologies, and a growing number of younger workers. An excerpt: "There is a revolution underway in manufacturing today that is ushering in a new era for the industry. If you take a step inside and look around one of today’s most advanced facilities, you’ll see it’s a far cry from the dark, dirty and dangerous rust-belt dungeons of manufacturing days gone by. Instead, these forward-thinking facilities are clean, bright, efficient workplaces that use some of the most cutting-edge technological advances available — robotics, 3D printing, mobile internet, cloud computing, big data and the Internet of Things (IOT) — to gain an edge in the marketplace with greater efficiencies, increased productivity, and other advantages that equate to a much healthier bottom line." When business works with local high school to develop and implement certification programs, the results can have a long term impact on the community: According to the National Association of Manufacturers (NAM), the skill gap for entry level workers in advanced manufacturing is growing at a startling rate. With approximately 30% of jobs requiring technical skills and only 17% of graduates having them, you can see how alarming this trend is. High Schools like Doss High School are looking to reverse this trend by offering students the chance to earn stackable credentials that they can take with them to any job:

These core competencies, taught by Amatrol through the MSSC certification program, helps graduates feel more comfortable and confident in job placements, feel more agile and communicate more effectively. The certifications are stackable credentials recognized by business and industry, and can give students a competitive advantage when applying for manufacturing positions. These programs are specifically designed for High Schools, and can complement core content in science, math, and other areas – which creates a win-win for schools! Learn more: contact an Education Specialist to learn about the certification options available for your high school students. Are you familiar with the term “data driven manufacturing”? Low cost sensors and the ability to connect them to the internet have made data collection easier than ever before. [U]sing data to reduce costs through next generation sales and operations planning, dramatically improved productivity, supply chain and distribution optimization, and new types of after-sales services. This video goes into greater detail about data driven manufacturing, courtesy of Modern Machine Shop: As manufacturing gets more technical, educators work to stay ahead of the curve by teaching students for 21st century careers. Schools are turning to industry-leading curriculum experts like Amatrol, FANUC, Lincoln Electric and Turbine Technologies to lend real-world credibility to teach advanced manufacturing processes. More than trouble-shooting and problem solving, manufacturers are looking for their next employees (your students) to be able to integrate highly technical skills into an established process to make current processes more efficient and cost-effective.

Moss has worked with leading manufacturers for over 40 years. If you’re looking to align your educational tools with local industry needs, contact us for a review. Our Education Specialists will ensure you align your curriculum with what is most relevant to your local industry. Further reading: Data-Driven Manufacturing  Beginning August 19th, Amatrol will be updating all of the student learning sites, including learnAmatrol.com and learnOxygen.com, from HTTP to HTTPS formatted websites. This added security measure is designed to more closely protect confidential student information as they use the eLearning websites. The HTTPS format provides added security for learner data to all of our customers. This changeover will not affect access codes, courses, passwords, quiz grades, or any other user information. The only difference is that data sent between your browser (e.g. Chrome, Firefox) and the Amatrol websites is encrypted for security. Amatrol will be making the transition to Https starting on Friday, August 19th at 3:00PM EDT. During the changeover, access to learnamatrol.com and learnoxygen.com will be unavailable. A notice of this impeding downtime has been added to the eLearning websites, allowing users sufficient time to adjust their training schedules. Questions? Contact Moss for assistance.  We often talk about the advanced skills positions available in today's manufacturing, but we can't forget about the importance of the fundamentals, the basic skills that employers assume candidates have when they hire. We came across an article in Manufacturing Today that highlights the need for basic assembly skills: There was a time, not long ago, when employers could rely on new hires to possess rudimentary knowledge of basic assembly methods, schematic diagrams, and proper use of hand tools. These skills were the result of individuals who grew up maintaining their cars. Yet that way of life is largely a thing of the past, much to the dismay of employers. The current focus on advanced technologies and high-end skills is crucial and necessary, but you cannot overlook the need for basic skills, such as the ability to install bearings, lubricate machine slides, or align couplings. These skills range from welding to assembly to how to use tools effectively. These fundamental skills are as crucial today as they ever have been. Click here to learn what several companies are doing to combat this skills gap, and how Amatrol is providing curriculum and tools to address this need.

The highly-regarded Brookings Institute recently published a compelling article by Senior Fellow, Mark Munro, " The Skills Supply Chain Must Change as Software Eats the World," about the changing face of workforce development. The article illuminates the recent evolution of "digitization," as well as exploring "a variety of training-system responses to the talent needs of industry." The impacts of software exist hand-in-hand with those of hardware, and they are long-term, so they require meaningful consideration by executives, educators and workers. Toyota Engineering and Manufacturing's Dennis Dio Parker addresses Toyota’s interest in having factory floor worker engaged with a particular "'technical core' of professional competencies, including in electronics, robotics controls, circuitry, and digital learning. 'We have to focus in detail on exactly what’s needed in talent coming into the company and whether potential workers have it,' said Parker. 'I will say we are having a difficult time procuring the talent we need because, first, there’s not enough of it now and second, we need that talent to be more talented, with more specific skills.'” |

AuthorYou have questions about STEM education? You're not alone! We're here to share ideas and provide thought-provoking commentary. Let us know your thoughts! Sign Up for Email Updates For Email Marketing you can trust. Categories

All

Archives

February 2017

|

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Training Equipment

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Training Equipment

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

RSS Feed

RSS Feed