The FANUC Advanced Automation Challenge 2.0 invites all CERT schools to work with local industry to create problem solutions. This challenge provides students the opportunity to improve their STEM skills and become familiar with the advanced manufacturing industry. This challenge encourages students to work with manufacturers to design a solution or solve a problem using FANUC products or an integrated solution with technology from FANUC, Rockwell, Cisco or Lincoln. Students (aka “Tomorrow’s Innovators”) will have the opportunity to test their STEM (science, technology, engineering, math) skills and critical thinking abilities. Students will interview a manufacturer to learn about their processes and consider potential opportunities to apply their skills and knowledge. Students will use their school’s robot, CNC, or advanced manufacturing technology to develop/design a workable solution and provide a demonstration. Creativity is encouraged - students decide how simple or complex their solution is. The goal of this open-ended challenge is to change the perception of what todays advanced manufacturers looks like and introduce manufacturers to Tomorrow’s Innovators. This challenge will prepare them for exciting STEM career opportunities, develop their problem-solving skills, and introduce them to real-world advanced manufacturing applications. Manufacturers need a workforce that is prepared to work in the new, Smart Factories of Industry 4.0. FANUC, together with Rockwell Automation, Cisco Systems, and Lincoln Electric, are committed to supporting education programs that serve the needs of the advanced manufacturing industry. Awards will include a FANUC Robot, a FANUC CNC Simulator, a Rockwell PLC/HMI package, FANUC Simulation software, and technology from Cisco and Lincoln, representing over $100,000 investment in STEM education programs.

0 Comments

Is your school seeking to attract non-traditional students to STEM-related welding and manufacturing technology programs? Are you struggling to direct students to a skilled trades career path? Here’s a report from The Morning Journal about a recent Careers in STEM event at Lorain County Community College for area high school students presented by the college’s chapter of the Society of Women Engineers. The college used a Lincoln Electric VRTEX® virtual reality welding simulator to engage students and let them try their hand at SMAW welding. LEARN MORE.

Students choose career paths for a variety of reasons. Gender norms are playing less of a factor as students are exposed to technologies (and potential career paths) earlier. What are you doing to encourage students to pursue studies (and careers) in Industrial Technology? We'd love to hear your tips in the comments section! Are you familiar with the term “data driven manufacturing”? Low cost sensors and the ability to connect them to the internet have made data collection easier than ever before. [U]sing data to reduce costs through next generation sales and operations planning, dramatically improved productivity, supply chain and distribution optimization, and new types of after-sales services. This video goes into greater detail about data driven manufacturing, courtesy of Modern Machine Shop: As manufacturing gets more technical, educators work to stay ahead of the curve by teaching students for 21st century careers. Schools are turning to industry-leading curriculum experts like Amatrol, FANUC, Lincoln Electric and Turbine Technologies to lend real-world credibility to teach advanced manufacturing processes. More than trouble-shooting and problem solving, manufacturers are looking for their next employees (your students) to be able to integrate highly technical skills into an established process to make current processes more efficient and cost-effective.

Moss has worked with leading manufacturers for over 40 years. If you’re looking to align your educational tools with local industry needs, contact us for a review. Our Education Specialists will ensure you align your curriculum with what is most relevant to your local industry. Further reading: Data-Driven Manufacturing Since Lincoln Electric introduced U/LINC, we have fielded many questions about this curriculum. We’re answering the three most common questions here:

As a welding expert, we would like your input – sign up for a 30 day free trial and tell us what you think. Would adding structured curriculum help your program succeed?  We often talk about the advanced skills positions available in today's manufacturing, but we can't forget about the importance of the fundamentals, the basic skills that employers assume candidates have when they hire. We came across an article in Manufacturing Today that highlights the need for basic assembly skills: There was a time, not long ago, when employers could rely on new hires to possess rudimentary knowledge of basic assembly methods, schematic diagrams, and proper use of hand tools. These skills were the result of individuals who grew up maintaining their cars. Yet that way of life is largely a thing of the past, much to the dismay of employers. The current focus on advanced technologies and high-end skills is crucial and necessary, but you cannot overlook the need for basic skills, such as the ability to install bearings, lubricate machine slides, or align couplings. These skills range from welding to assembly to how to use tools effectively. These fundamental skills are as crucial today as they ever have been. Click here to learn what several companies are doing to combat this skills gap, and how Amatrol is providing curriculum and tools to address this need.

The highly-regarded Brookings Institute recently published a compelling article by Senior Fellow, Mark Munro, " The Skills Supply Chain Must Change as Software Eats the World," about the changing face of workforce development. The article illuminates the recent evolution of "digitization," as well as exploring "a variety of training-system responses to the talent needs of industry." The impacts of software exist hand-in-hand with those of hardware, and they are long-term, so they require meaningful consideration by executives, educators and workers. Toyota Engineering and Manufacturing's Dennis Dio Parker addresses Toyota’s interest in having factory floor worker engaged with a particular "'technical core' of professional competencies, including in electronics, robotics controls, circuitry, and digital learning. 'We have to focus in detail on exactly what’s needed in talent coming into the company and whether potential workers have it,' said Parker. 'I will say we are having a difficult time procuring the talent we need because, first, there’s not enough of it now and second, we need that talent to be more talented, with more specific skills.'” You just hired a new instructor for your welding school with years of skilled trade experience. You know they’ll be a good mentor for your students. But what does he or she know about technical instruction? Has he ever developed curriculum for a year-long program educational program? What will he teach on Day 1? Consider U/LINC™ Curriculum from Lincoln Electric – We have over 1000 lesson plans, student activities, assessments, videos and presentations covering everything from welding safety to welding engineering and everything in between. Let your instructor teach his trade – We’ll do the rest.

Forbes magazine recently published a compelling article, 3 Ways The Skills Gap Offers Opportunity, about the state and evolution of the workforce for skilled workers. The article aims to dispel the myth that a four-year degree is the optimal path to a prosperous future, reminding readers, for example that, “today around 13 million Americans, many with college degrees, are unemployed, and that does not include those who are underemployed or have given up trying to find work. Yet, nearly five million jobs remain unfilled. Jobs in advanced manufacturing, electrical trades, jobs in healthcare and cyber-security to name just a few.”

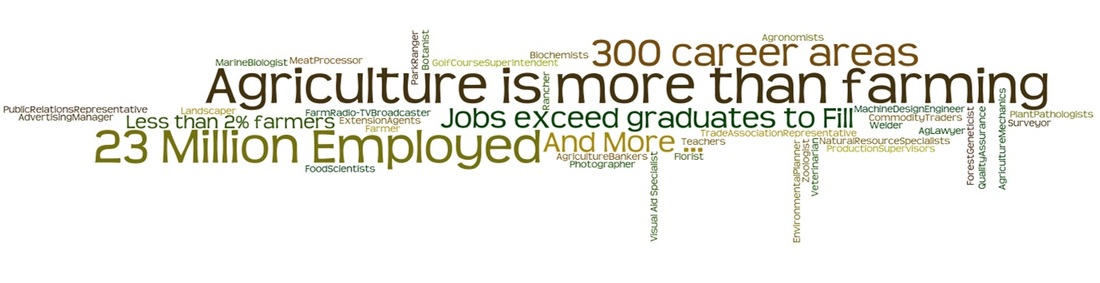

The economy needs more skilled workers, who gain mastery through hands-on work and via vocational and technical training. The article further points out how the path of vocational and technical training might best be navigated, and how that path helps people avoid the often immense debt associated with a four-year college degree, while also providing “real world,” industry recognized skills in a hands-on context.  If you teach in an ag classroom, you know your students are as diverse as they come. Students may be drawn to agriculture because of family history or a love of animals, but what they learn in the classroom has the power to transform in ways we haven’t thought of yet. Students who study agriculture go on to careers ranging from biotechnology to machinists and engineers. No other field of study has such broad implications. What do students need to master to be successful in ag-related careers? We’ve developed a list of the essential subject matter for ag students:

What subject matter is a must-have for your agriculture education programs? Let us know in the comment section! Moss can help you enhance your agriculture programs – see our Agriculture Education page for more information. When you hear the word “manufacturing,” what images does it conjure up? If you are like most, you have visions of dirty, unsafe construction floors where people repeat the same function all day long, day after day. If this is what you see, you may need to update your image: manufacturing as cleaner and more high-tech than ever before. And manufacturing is driving the nation’s economy forward. According to the latest report from the U.S. Bureau of Labor Statistics, U.S. manufacturing companies added a substantial 29,000 new jobs in January this year alone.

Manufacturing jobs are plentiful, but the face of these jobs is changing. Recruiters and hiring managers are looking for candidates with an advanced skill set. These are skills that educators can ensure their students possess before they graduate and join the workforce. Certain skills will ensure students are marketable, and that their skills will allow them to be successful on their first day of a new job. What Employers Want to Share with Educators:

Get employers to compete for your students. In order to connect your classroom with “real world” learning opportunities, you need to have the proper tools in place. Moss has training and certification tools to ensure your students will be successful during their next phase. These tools are appropriate for both technical high schools and colleges. Contact us today for a no-obligation consultation with an Education Specialist. |

AuthorYou have questions about STEM education? You're not alone! We're here to share ideas and provide thought-provoking commentary. Let us know your thoughts! Sign Up for Email Updates For Email Marketing you can trust. Categories

All

Archives

February 2017

|

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- APT Manufacturing

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Equipment

- FANUC-Robotics & CNC

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- Levil Technology-CNC

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- APT Manufacturing

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Equipment

- FANUC-Robotics & CNC

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- Levil Technology-CNC

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

RSS Feed

RSS Feed