The FANUC Advanced Automation Challenge 2.0 invites all CERT schools to work with local industry to create problem solutions. This challenge provides students the opportunity to improve their STEM skills and become familiar with the advanced manufacturing industry. This challenge encourages students to work with manufacturers to design a solution or solve a problem using FANUC products or an integrated solution with technology from FANUC, Rockwell, Cisco or Lincoln. Students (aka “Tomorrow’s Innovators”) will have the opportunity to test their STEM (science, technology, engineering, math) skills and critical thinking abilities. Students will interview a manufacturer to learn about their processes and consider potential opportunities to apply their skills and knowledge. Students will use their school’s robot, CNC, or advanced manufacturing technology to develop/design a workable solution and provide a demonstration. Creativity is encouraged - students decide how simple or complex their solution is. The goal of this open-ended challenge is to change the perception of what todays advanced manufacturers looks like and introduce manufacturers to Tomorrow’s Innovators. This challenge will prepare them for exciting STEM career opportunities, develop their problem-solving skills, and introduce them to real-world advanced manufacturing applications. Manufacturers need a workforce that is prepared to work in the new, Smart Factories of Industry 4.0. FANUC, together with Rockwell Automation, Cisco Systems, and Lincoln Electric, are committed to supporting education programs that serve the needs of the advanced manufacturing industry. Awards will include a FANUC Robot, a FANUC CNC Simulator, a Rockwell PLC/HMI package, FANUC Simulation software, and technology from Cisco and Lincoln, representing over $100,000 investment in STEM education programs.

0 Comments

If you have a FANUC CERT program, you already know the benefits of adding robotics to your training programs. With FANUC America's educational products, students can learn to utilize the latest automation technology in robots, CNC, ROBODRILL, and integrated solutions while applying science, technology, engineering, and math (STEM) skills. Some of the successful approaches used by educational institutions are:

Are you getting the most out of your robotics program? Maximize your program with one or more of the following tools:

These are just a few of the options available for FANUC CERT training programs. Let us help you customize and enhance your program, while improving student outcomes. Contact Moss today for competitive pricing. Are you familiar with the term “data driven manufacturing”? Low cost sensors and the ability to connect them to the internet have made data collection easier than ever before. [U]sing data to reduce costs through next generation sales and operations planning, dramatically improved productivity, supply chain and distribution optimization, and new types of after-sales services. This video goes into greater detail about data driven manufacturing, courtesy of Modern Machine Shop: As manufacturing gets more technical, educators work to stay ahead of the curve by teaching students for 21st century careers. Schools are turning to industry-leading curriculum experts like Amatrol, FANUC, Lincoln Electric and Turbine Technologies to lend real-world credibility to teach advanced manufacturing processes. More than trouble-shooting and problem solving, manufacturers are looking for their next employees (your students) to be able to integrate highly technical skills into an established process to make current processes more efficient and cost-effective.

Moss has worked with leading manufacturers for over 40 years. If you’re looking to align your educational tools with local industry needs, contact us for a review. Our Education Specialists will ensure you align your curriculum with what is most relevant to your local industry. Further reading: Data-Driven Manufacturing  We often talk about the advanced skills positions available in today's manufacturing, but we can't forget about the importance of the fundamentals, the basic skills that employers assume candidates have when they hire. We came across an article in Manufacturing Today that highlights the need for basic assembly skills: There was a time, not long ago, when employers could rely on new hires to possess rudimentary knowledge of basic assembly methods, schematic diagrams, and proper use of hand tools. These skills were the result of individuals who grew up maintaining their cars. Yet that way of life is largely a thing of the past, much to the dismay of employers. The current focus on advanced technologies and high-end skills is crucial and necessary, but you cannot overlook the need for basic skills, such as the ability to install bearings, lubricate machine slides, or align couplings. These skills range from welding to assembly to how to use tools effectively. These fundamental skills are as crucial today as they ever have been. Click here to learn what several companies are doing to combat this skills gap, and how Amatrol is providing curriculum and tools to address this need.

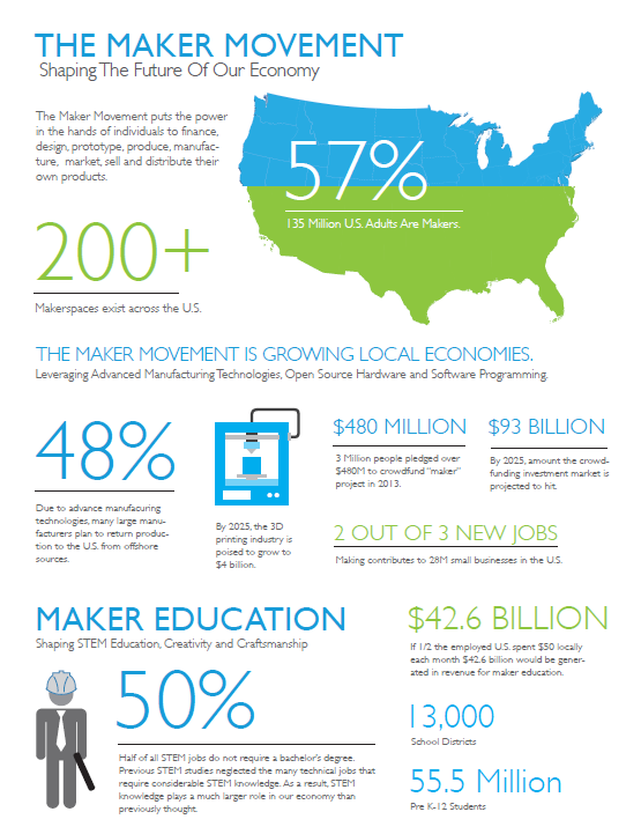

The highly-regarded Brookings Institute recently published a compelling article by Senior Fellow, Mark Munro, " The Skills Supply Chain Must Change as Software Eats the World," about the changing face of workforce development. The article illuminates the recent evolution of "digitization," as well as exploring "a variety of training-system responses to the talent needs of industry." The impacts of software exist hand-in-hand with those of hardware, and they are long-term, so they require meaningful consideration by executives, educators and workers. Toyota Engineering and Manufacturing's Dennis Dio Parker addresses Toyota’s interest in having factory floor worker engaged with a particular "'technical core' of professional competencies, including in electronics, robotics controls, circuitry, and digital learning. 'We have to focus in detail on exactly what’s needed in talent coming into the company and whether potential workers have it,' said Parker. 'I will say we are having a difficult time procuring the talent we need because, first, there’s not enough of it now and second, we need that talent to be more talented, with more specific skills.'” We've been hearing a lot about the Maker Movement recently. But what is the Maker Movement? Adweek hits it on the head: The maker movement, as we know, is the umbrella term for independent inventors, designers and tinkerers. A convergence of computer hackers and traditional artisans, the niche is established enough to have its own magazine, Make, as well as hands-on Maker Faires that are catnip for DIYers who used to toil in solitude. Makers tap into an American admiration for self-reliance and combine that with open-source learning, contemporary design and powerful personal technology like 3-D printers. The creations, born in cluttered local workshops and bedroom offices, stir the imaginations of consumers numbed by generic, mass-produced, made-in–China merchandise. In other words, the Maker Movement is home to the do-ers, the inventors, the designers of our generation. The people who use creativity to create and do.

Makers benefit from a space that has the tools to spur their creativity - whether it's a Fab Lab or a Makerspace - this space is designed to give people the tools to "figure it out." Most are filled with the tools of the trade, from 3D printers, lasers, robotics, and more. These people are looking for efficiencies, and driving creators and manufacturers forward with new innovation. Have you developed or used a Makerspace? What makes a successful Makerspace? Share your tips in the comments section.  While catching up on one of our favorite columns, we came across an interesting piece on Makerspaces. A Makerspace is a dedicated space in a school, often in a library, resource room or common area, which encourages creativity and exploration. Outside of a typical classroom, they provide a safe space where students of all ages can build, design and test their own theories. Makerspaces can come in a lot of different forms and contain a host of different tools, but they generally have a few things in common:

A Makerspace can have a huge impact on educational outcomes, but seem like a fun break from the normal classroom routine for your students. Does your school have a Makerspace? Tell us about it – share your Makerspace Best Practices in the comments section! Additional reading from Pitsco Education: FANUC America is inviting all FANUC CERT schools to design the next Project Based Learning (PBL) kit!

The FANUC Advanced Automation Challenge provides a unique opportunity to show us your innovations. FANUC is asking Tomorrow's Innovators to highlight the utilization of robotic automation and technology through Project Based Learning that exemplify STEM learning outcomes. Show us your creative ideas using Science, Technology, Engineering, and Math to problem solve real-world challenges and strengthen your STEM knowledge. Great prizes at stake, including: 1st place: (1) FANUC MliA Tabletop robot and (1) $1500 scholarship award 2nd place: (2) Teach Pendants and Conversion Kits, (10) Academic ROBOGUIDE Licenses*, and (1) $500 scholarship award 3rd place: (10) Academic ROBOGUIDE Licenses* and (1) $500 scholarship award Click here for submission guidelines, as well as the official submission form: Many STEM projects focus mainly on the STE-, neglecting the M(ath) component. Meanwhile mathematics proficiency in high school students has fallen to 32% -- disqualifying many graduates from entry-level jobs. Our team of roboticists, engineers, teachers and professors are dedicated to fixing the education system using 21st century technology, bringing math to life and preparing students for their future, ensuring their career and college readiness.

RobotsLAB BOX moves abstract mathematical concepts away from the white board and transforms them into real life demonstrations. Students can see a quadcopter teach quadratic equations, a rover demonstrate angular and linear concepts conversions, and a robotic arm will show you what the word cosine really means. Why Teach Math with RobotsLAB BOX?

When you hear the word “manufacturing,” what images does it conjure up? If you are like most, you have visions of dirty, unsafe construction floors where people repeat the same function all day long, day after day. If this is what you see, you may need to update your image: manufacturing as cleaner and more high-tech than ever before. And manufacturing is driving the nation’s economy forward. According to the latest report from the U.S. Bureau of Labor Statistics, U.S. manufacturing companies added a substantial 29,000 new jobs in January this year alone.

Manufacturing jobs are plentiful, but the face of these jobs is changing. Recruiters and hiring managers are looking for candidates with an advanced skill set. These are skills that educators can ensure their students possess before they graduate and join the workforce. Certain skills will ensure students are marketable, and that their skills will allow them to be successful on their first day of a new job. What Employers Want to Share with Educators:

Get employers to compete for your students. In order to connect your classroom with “real world” learning opportunities, you need to have the proper tools in place. Moss has training and certification tools to ensure your students will be successful during their next phase. These tools are appropriate for both technical high schools and colleges. Contact us today for a no-obligation consultation with an Education Specialist. |

AuthorYou have questions about STEM education? You're not alone! We're here to share ideas and provide thought-provoking commentary. Let us know your thoughts! Sign Up for Email Updates For Email Marketing you can trust. Categories

All

Archives

February 2017

|

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Training Equipment

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Training Equipment

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

RSS Feed

RSS Feed