How well do you know the Engineering Design Process (EDP)? How well do your students know it? If you answered “not at all” to either of those questions, think again. You likely follow some of the steps in your everyday activities. The focus of the EDP is problem solving. I’m sure you’ve problem solved already today. Deciding what to wear, which errands to complete, and where to eat are examples of everyday situations where you subconsciously use the EDP. Let’s review the steps to see if you agree.

The Engineering Design Process is something we use more often than we realize. However, many kids today do not have this same skill set and often lack problem-solving skills. So, let’s look at how a Pitsco Maker Space Project can be used to teach the EDP. The KaZoon Kite Maker Project spans all three of our leveled makerspace packages.

Blog re-printed from Pitsco Education Community Blog. Content written by Kristina Davis, Education Program Designer.

2 Comments

ITC: Building the Workforce of Tomorrow Today's economy requires workforce members to possess a range of technical skills that can be used in team-based environments, so current students must develop both specialized hands-on skills and essential workplace skills like problem solving, teamwork and effective communication. Amatrol's Integrated Technology Concepts (ITC) program offers technical skills training across a wide range of real-world areas through project-based learning while interweaving essential workplace skills through team-based projects. This combination of skills and knowledge will put students on a path toward exciting career opportunities in areas like supply chain, automated distribution, engineering, medical, and more. Strong STEM Integration Facilitates College Credit, Industrial Certification Prep In addition to essential workplace skills, ITC emphasizes STEM skills. Combining STEM skills with hands-on applications helps to meld theory and practice in student's mind, which will assist them in knowledge retention and building skills for more advanced concepts. This STEM integration allows for many schools to establish transferable college credit hours for ITC courses. Amatrol's ITC proram is also a strong foundation in preparation for several industrial certification. Amatrol partners with organizations including NIMS, MSSC, ITEEA, and more for certifications like MSSC's Certifiied Production Technician and NIMS' Industrial Technology Maintenance certifications. Foundational Systems for Successful Careers The first step of ITC is Amatrol's Enterprise Systems courses, which provides the framework for integrating multiple technical skills successfully using teamwork. Students begin by exploring different technology sectors before studying team concepts, product design, business presentations, internet research, and much more. ITC Quick Facts

Want to learn more about this (or any other Industrial Technology program from Amatrol)? Contact Moss for an in-depth look today. Afinia is always looking to improve the user experience for educators, which is why they asked for your feedback, and incorporated your suggestions into the new and improved H800+. The updated 3D printer includes:

Award-Winning InnovationThe Afinia H800+ 3D printer won the RAPID 2015 Exhibitor Innovation Award, which recognizes the most innovative new products or services exhibited at RAPID that are judged to have the greatest potential impact on the industry. Afinia 3D was selected as the recipient by the Society of Manufacturing Engineers’ (SME) Rapid Technologies & Additive Manufacturing (RTAM) Committee. TechZone 360 also chose the Afinia H800+ 3D Printer for their 2015 3D Printing Excellence Award, citing Afinia 3D as a leader within the 3D printing industry. The TechZone 360 3D Printing Excellence Award identifies products, services, and applications that are driving the growth and evolution of 3D Printing from niche market hype to mainstream reality. Learn More This printer boasts the largest print surface for large-format designs, and superior print resolution to similar 3D printers on the market. Download an updated spec sheet, or contact Moss for more information. Weigh in: will these improvements make a difference in your classroom? How will you incorporate this updated technology? Whether you are building a Makerspace of Fab Lab, you have undoubtedly considered a CNC Router. CNC technology is a key component of fabrication, but the technology is as diverse as the applications. CNC equipment is designed to route, carve, drill, and engrave in wood, plastic, foam, aluminum and other materials for a wide range of applications.

CNC routers, plasma cutters and laser equipment make it easy and exciting for educators to prepare students for the technical manufacturing jobs of tomorrow. Students understand modern manufacturing challenges, turning design concepts into reality on industry standard equipment. Choosing a CNC Router When choosing a CNC Router, consider the following components:

At Moss, we represent Techno CNC Systems, FANUC, and ez Router – we can provide options based on your program goals and budget considerations. Let us help you develop your FabLab or Makerspace. Tell us – what is the single biggest consideration you have when looking at CNC Routers? Are you looking for ideas on how to integrate 3D printing into your existing STEM curriculum? You're not alone! Project-based learning and 3D printing are pivotal avenues for teaching STEM subjects, engaging students on new levels, and preparing them for future careers. Afinia offers several 3D Printing STEM Kits, which support project-based learning in the classroom.

Each pack comes with student workbooks and a teacher’s guide to help you seamlessly integrate the projects into your curriculum. Available STEM Kits include:

Integrating 3D printing into existing STEM programs is easy with these project-based units. Learn more - download this informational file today, or contact your Education Specialist for more information. When business works with local high school to develop and implement certification programs, the results can have a long term impact on the community: According to the National Association of Manufacturers (NAM), the skill gap for entry level workers in advanced manufacturing is growing at a startling rate. With approximately 30% of jobs requiring technical skills and only 17% of graduates having them, you can see how alarming this trend is. High Schools like Doss High School are looking to reverse this trend by offering students the chance to earn stackable credentials that they can take with them to any job:

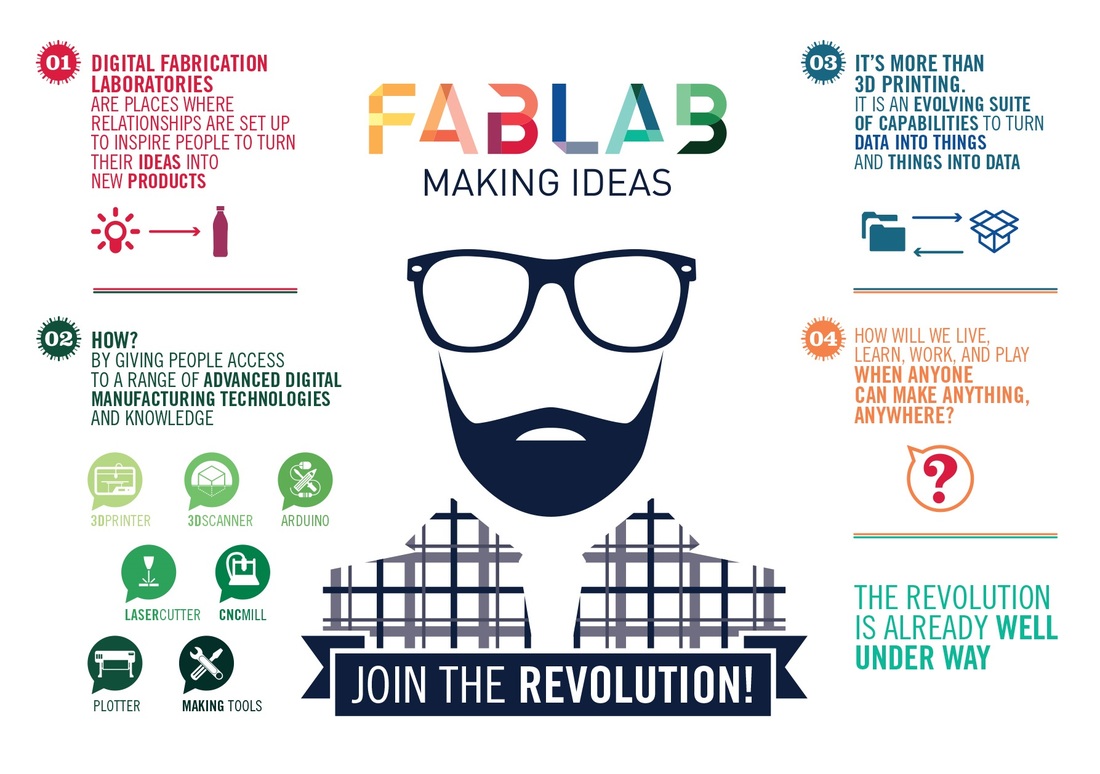

These core competencies, taught by Amatrol through the MSSC certification program, helps graduates feel more comfortable and confident in job placements, feel more agile and communicate more effectively. The certifications are stackable credentials recognized by business and industry, and can give students a competitive advantage when applying for manufacturing positions. These programs are specifically designed for High Schools, and can complement core content in science, math, and other areas – which creates a win-win for schools! Learn more: contact an Education Specialist to learn about the certification options available for your high school students. Does your design and engineering program have a Fab Lab? If not, your students may be missing some key opportunities. Fab Labs are popping up in colleges and technical centers, offering tools and technology enabling students to create and refine. A Fab Lab, short for Fabrication Lab, is ideal for students to design and create prototypes, and is filled with tools designed to enable students through the design process. Fab Labs are most popular in schools with strong engineering and design progams.

While each Fab Lab is different, they have similar components. If you are designing a Fab Lab, consider implementing these elements:

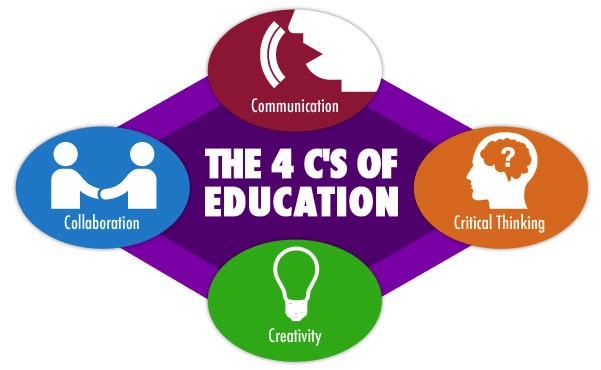

Fab Labs can complement in-class instruction, and provide a “lab” environment for coursework. We want to hear from you – are you considering adding a Fab Lab? What tools are you looking for to complete (or begin) your Fab Lab design? We hear a lot about how important it is for today’s students to develop 21st century skills, in addition to ‘the basics.' The 4 C's (Communication, Collaboration, Critical Thinking, and Creativity) are often described as the ‘new basics.’ Learn how 3D design and printing can help students develop these vital new basics on Makers Empire's blog.

We want to hear from you -- do you use 3D printing in your classroom? How is it helping you teach the 4 C's of Education?  Consider this student: Abby is an agriculture student who was raised on a family farm. She sees her dad struggle with the same piece of equipment year after year. She thinks she has a simple solution. Her school has a Makerspace, and she has printed a part in 3D that she thinks will solve the problem. She has talked with her instructor about sharing the same design to other local farmers that have the same issue as her dad. Is Abby ready for an Entrepreneurship course? Entrepreneurs come in all shapes and sizes. While Abby is looking for a simple solution to a recurring problem, and is looking to share her solution with others. She has the shades of being a developing Entrepreneur. Entrepreneurship coursework used to live in the Business departments almost exclusively. As we deepen our understanding about how entrepreneurs views obstacles, assess risk, develop solutions, innovate and solve problems, we are beginning to realize that Entrepreneurship coursework can benefit not only business students, but also agriculture students, engineering students, design students… In short, anyone who innovates and problem solves could benefit from the framework laid out in Entrepreneurship coursework. Entrepreneurship coursework is designed to provide:

Many schools are looking to develop entrepreneurship coursework. We can help schools connect the dots with smart tools from Pitsco Education (STEM framework) and Startup Genius (Entrepreneurship). Tell us: what are you looking for in an Entrepreneurship program? Despite their tuxedoed appearance, penguins aren’t always well mannered. In the aftermath of one particular penguin scuffle among endangered African Penguins at Mystic Aquarium, Yellow/Purple (AKA “Purps”) was found to have a nonfunctional flexor tendon in her ankle. Much like an injury to a person’s Achilles heel, damage to a penguin’s flexor tendon leads to pain and difficulty in motion. Once Purps’ injury was identified, the veterinary staff at Mystic Aquarium took action with a handmade boot to immobilize, protect and support the damaged foot. Yet the animal care team knew more modern solutions were available that would not only be more durable and less cumbersome for the small bird, but also require less time than handcrafting the boot. Mystic Aquarium’s Chief Clinical Veterinarian, Dr. Jen Flower, proposed 3D printing. Blog courtesy of 3D Systems.

|

AuthorYou have questions about STEM education? You're not alone! We're here to share ideas and provide thought-provoking commentary. Let us know your thoughts! Sign Up for Email Updates For Email Marketing you can trust. Categories

All

Archives

February 2017

|

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Training Equipment

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Training Equipment

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

RSS Feed

RSS Feed