rWorkers today are called on to be subject matter experts in what they do. Gone are the days when someone can clock in and do a repetitive skill for hours. Today's workforce demands more: the same worker must now know how to assess, troubleshoot, fix, and communicate in a much more global sense. Work is less silo-ed, more interconnected with other teams. Added requirements are making it difficult for employees to stay ahead of demands, creating a skills gap. How do you train employees for these enhanced skill requirements? Many are turning to Registered Apprenticeships to fill the void. According to Why Apprenticeships are Taking Off, registered apprenticeships, not to be confused with less formal or company-specific apprentice programs, have five defining features:

Apprenticeships allow employers to hire and train workers with the necessary skills, while students can avoid an unnecessary financial burden of student loans. According to the Department of Labor, 87 percent of apprentices are employed after completing apprenticeship programs, with an average starting salary above $50,000. Registered Apprenticeship programs make a lot of sense in both urban and rural settings, and are easier to implement and facilitate than you may realize. In fact, the U.S. Department of Labor offers several registered Apprenticeship programs, backed by curriculum from leaders in education, like Amatrol. Looking to learn more, or get started today? Contact Moss for learning opportunities.

0 Comments

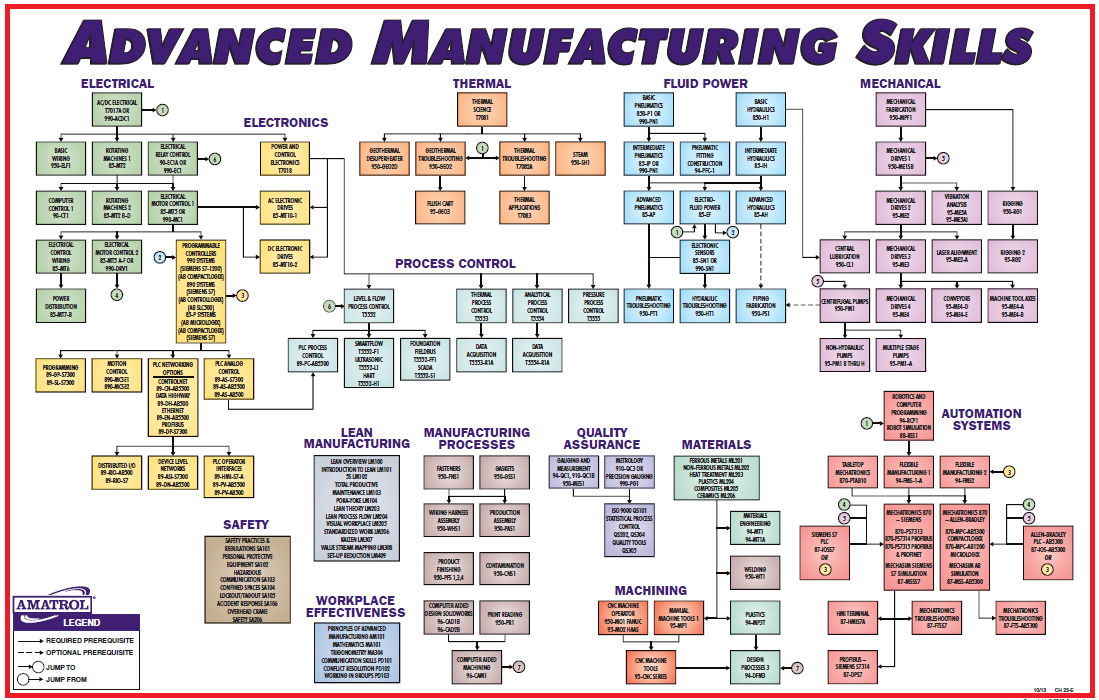

Moss is proud to offer equipment and curriculum from Amatrol’s Advanced Manufacturing program. Amatrol’s industry leading equipment and curriculum is developed in partnership with industry to deliver job ready, industry relevant skills. Working closely with companies like Caterpillar, Tropicana and many others Amatrol has designed equipment for work place success.

Key Features

Want to ensure you are covering your bases and addressing the skills training most needed in your region? Check out the skills chart, which aligns coursework to job-ready skills: When business works with local high school to develop and implement certification programs, the results can have a long term impact on the community: According to the National Association of Manufacturers (NAM), the skill gap for entry level workers in advanced manufacturing is growing at a startling rate. With approximately 30% of jobs requiring technical skills and only 17% of graduates having them, you can see how alarming this trend is. High Schools like Doss High School are looking to reverse this trend by offering students the chance to earn stackable credentials that they can take with them to any job:

These core competencies, taught by Amatrol through the MSSC certification program, helps graduates feel more comfortable and confident in job placements, feel more agile and communicate more effectively. The certifications are stackable credentials recognized by business and industry, and can give students a competitive advantage when applying for manufacturing positions. These programs are specifically designed for High Schools, and can complement core content in science, math, and other areas – which creates a win-win for schools! Learn more: contact an Education Specialist to learn about the certification options available for your high school students. Forbes magazine recently published a compelling article, 3 Ways The Skills Gap Offers Opportunity, about the state and evolution of the workforce for skilled workers. The article aims to dispel the myth that a four-year degree is the optimal path to a prosperous future, reminding readers, for example that, “today around 13 million Americans, many with college degrees, are unemployed, and that does not include those who are underemployed or have given up trying to find work. Yet, nearly five million jobs remain unfilled. Jobs in advanced manufacturing, electrical trades, jobs in healthcare and cyber-security to name just a few.”

The economy needs more skilled workers, who gain mastery through hands-on work and via vocational and technical training. The article further points out how the path of vocational and technical training might best be navigated, and how that path helps people avoid the often immense debt associated with a four-year college degree, while also providing “real world,” industry recognized skills in a hands-on context. When you hear the word “manufacturing,” what images does it conjure up? If you are like most, you have visions of dirty, unsafe construction floors where people repeat the same function all day long, day after day. If this is what you see, you may need to update your image: manufacturing as cleaner and more high-tech than ever before. And manufacturing is driving the nation’s economy forward. According to the latest report from the U.S. Bureau of Labor Statistics, U.S. manufacturing companies added a substantial 29,000 new jobs in January this year alone.

Manufacturing jobs are plentiful, but the face of these jobs is changing. Recruiters and hiring managers are looking for candidates with an advanced skill set. These are skills that educators can ensure their students possess before they graduate and join the workforce. Certain skills will ensure students are marketable, and that their skills will allow them to be successful on their first day of a new job. What Employers Want to Share with Educators:

Get employers to compete for your students. In order to connect your classroom with “real world” learning opportunities, you need to have the proper tools in place. Moss has training and certification tools to ensure your students will be successful during their next phase. These tools are appropriate for both technical high schools and colleges. Contact us today for a no-obligation consultation with an Education Specialist. Finding the right career fit is a challenge most students face and when asked what they want to do professionally when they graduate, the choices can be overwhelming. As a way to ease the transition for students making strides to their prospective career pathway, CEV Multimedia announces the addition of the Career Cluster Interest Inventory (CCII) tool to its comprehensive iCEV platform. The CCII provides assistance to students from eighth grade to higher education during the critical steps of education and career planning. A student completes the interest inventory within a 15- to 20-minute time period and receives information on a career cluster that best fits the student’s interests and skills. Career clusters, 16 groupings of related occupations developed by the U.S. Department of Education, provide essential knowledge and skills to guide in developing programs of study to bridge secondary and postsecondary curriculum. The clusters also assist in creating individual student plans of study for a complete range of career options. "This is an important addition to the CTE curriculum offered through iCEV that will assist students and educators alike in studying and exploring various career paths by identifying an interest pattern based on responses of career and activity related questions," said Dusty Moore, iCEV President. "Additionally, schools value survey tools to gain an understanding of the courses they need to offer to meet their students' needs and career aspirations."

Upon completing the inventory and being matched with a cluster, students are guided to post-secondary information and specific occupations. CCII complements the current iCEV career curriculum nicely as it allows a student to complete the interest inventory, identify their top cluster choices, then dive into the curriculum to watch videos, listen to industry experts via career interviews and complete projects to provide a better understanding of the clusters. After completing the study, students take a post-evaluation survey to see how their work impacted their original decisions. "The Career Cluster Interest Inventory enriches what we can offer to iCEV users and better connects them to the best education path leading towards their career choice," Moore said. "Students are able to look for general information on their career interests, as well as seek specific career titles, the credentials needed and college majors." Developed by CEV Multimedia, iCEV offers practical, interactive learning with professional demonstrations to prepare students for postsecondary education and high-skill, high-demand careers. Educators can quickly monitor, track and engage students directly through the platform’s interactive lessons. Through iCEV, students can also enhance their career training with industry-backed certifications. “You go into high school and everyone is talking to you about, well, you have got to go to college to be successful and you have to go to a four-year university, you will be nothing without a bachelor’s degree. It really puts so much pressure on your shoulders to do well at everything you do. And in high school, that was a really hard thing to deal with.” - Keihen Kitchen, student Like many students, Kitchen was looking for real, hands-on career opportunities. She was encouraged to attend a four-year university when a two-year technical school gave her the opportunities and the skills she needed for success in the engineering field.

She found an ideal program for her needs at Cuyahoga Community College in Cleveland, a school that uses Amatrol to teach industry-ready skills. They work closely with the local industries when developing coursework, and turned to Amatrol for the programs that aligned with the needs of the local workforce. Students like Kitchen are benefiting from being job ready with a two-year degree. Community Colleges and Technical Schools are filling an important niche in today’s workforce by offering targeted skills training programs that align with local business need. It’s a win-win for students and local industry alike. When the right curriculum is in place, whether welding programs, skills training or otherwise, students join the workforce prepared for the local job market. Students know they have stackable credentials, and employers can feel confident in the knowledge base of their new hires. Remind students that there are many paths to success. Read the full transcript of the program here:  Your students have something to say about the direction their education is taking. Believe it – more students are taking an active role in crafting the direction of their training opportunities. Your students want to tell you a few things about the curriculum you choose. In this fast-paced, high-tech, consumer-driven world, students want to know that what they are learning today will be relevant in the real world. They also care about HOW they learn, and how you could make it better for them. (Here’s a hint: they prefer simulators in most situations!) Here are the top six things they have to say: “We learn just as effectively on a simulator as we do on the real thing.” Many educators worry that simulators aren’t life-like, and won’t provide adequate training for real situations. However, simulators have taken a page from the gaming industry and have built better graphics into modern-day simulators, making the simulations more true and engaging than ever before. Need proof? Check out the simulation on SimLog’s Forklift series here. “We need your feedback more than ever.” Whether you are using a welding simulator, a heavy equipment simulator, or something to teach pneumatics, simulation can play a key role in the education process. As an educator, you can identify specific opportunities for improvement at the spot where the student missed the target. Often, you can download a record of the simulation and coach directly to a student’s need. “We will be more engaged with the use of technology.” Integrating technology into the classroom drives engagement. Students today have grown up with laptops, smart phones, and mobile devices. They learn through the use of technology – classrooms are adapting to suit the way students learn benefits the student’s final outcomes. “The same tool can be used with multiple students.” Every educator is looking for a cost-effective way to replicate the same education from student to student. Furnishing each student with one-and-done supplies gets costly, and takes up storage space that a lot of schools don’t have. Tools like zSpace and CyberScience allow you to replicate the same dissection for multiple students – without sourcing dissection materials for each student. “We still get the hands on experience.” Many schools are afraid that the hands on experience will be lost with simulation software. However, the opposite is the case – when a school uses simulation software to teach the fundamentals, they can provide a much more meaningful experience for students who pursue advanced coursework. “We get it – budgets are tight.” Simulators are cost-effective – meaning that they can produce results with a much price tag. Students pursuing a variety of subject matters, though, can benefit from cost-effective simulation. From science to heavy machinery, there are simulators appropriate for the inquiring student, and can positively affect student outcomes. Simulators provide a more cost-effective, more sustainable alternative to the old methods. Ready to investigate? Check out Moss' cost-effective simulation options: Have you used simulation in your classroom? Tell us about it in the comments section!

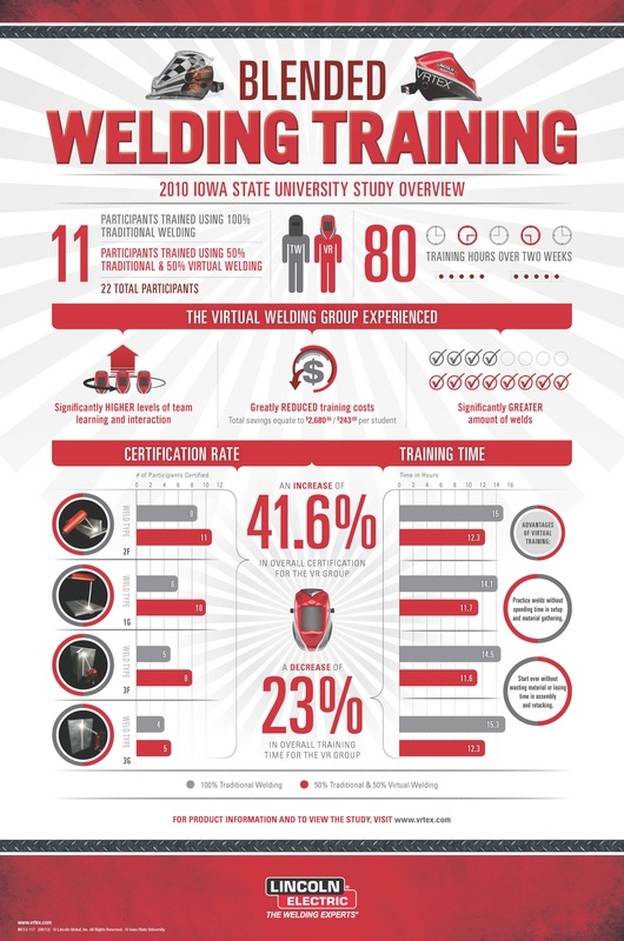

Entering its second century, the welding profession is maturing, with many employers requiring more exposure to robotic automation, advanced equipment, exotic materials, specialized code certification, theory, welding procedure specifications and more. With advances and specialization, there is a growing need for welders who understand more than how to hold a torch and join metal. As a result, public, private and skilled trade schools at every level are developing new education programs to designed to deliver the workforce industry is demanding today to remain globally competitive. In parallel, the need for skilled welding instructors and appropriate curriculum is growing as workforce development partnerships take hold and federal and state grant funds become available. 7 Essential Components of a Successful Welding Program 1. Curriculum – A well-designed welding program will include curriculum that covers technique, industry trends, and introductions to the different areas of welding. 2. Training Equipment – welding is a hands-on course, so real world training opportunities are a must. Training equipment should include an introduction to ARC welding, TIG welding, MIG welding, and FCAW welding. 3. Welding Safety -- For an ARC welder, safety practices and personal protective equipment, when used properly, protect against potential hazards. A robust training program will inform and remind students about safe shop welding practices. 4. Hands-On Practice – Many welding programs teach with a mix of virtual and hands-on training. Welding simulators, like the RealWeld Trainer will teach essential skills in a controlled environment, while Robotic Education Cell 2.0 will educate students on robotics in welding. 5. Apprenticeship Opportunities – Different techniques widely vary in the field. Pairing an inexperienced welder with a more seasoned professional will allow students to gain industry knowledge while working toward certification. Apprenticeships often set up long-standing mentor relationships. 6. Certification – industry recognized credentials, like certifications offered by Lincoln Electric, will add credibility to students as they enter the workforce. 7. Career Connections – According to Chron, welders have a strong career outlook in the coming years, anticipating 15% growth in the field. Welding programs should have strong ties to the local workforce and supply a steady stream of qualified labor to local employers. Welding programs are a significant part of Career and Technical Education. Need help assessing your program? Contact Moss for a free consultation or to set up a live demonstration*.

*Demonstrations available in Iowa, Illinois, Nebraska and South Dakota. |

AuthorYou have questions about STEM education? You're not alone! We're here to share ideas and provide thought-provoking commentary. Let us know your thoughts! Sign Up for Email Updates For Email Marketing you can trust. Categories

All

Archives

February 2017

|

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Training Equipment

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Training Equipment

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

RSS Feed

RSS Feed