The Great Debate – Additive vs. Subtractive Manufacturing (What Your Students Need to Know!)12/1/2016 Experts are discussing an important shift in manufacturing technology: which is more beneficial, additive or subtractive manufacturing. Let's face it - it's a crowded field, full of technologies and applications. Fictiv discusses the future of production in this blog post, and how people are choosing technology for tomorrow’s industry. In today’s maker-climate, each technology has advantages, and implications for your students.

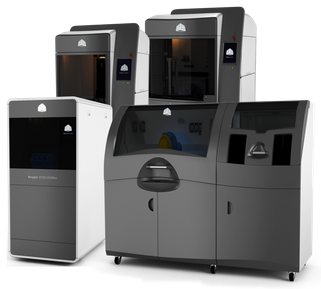

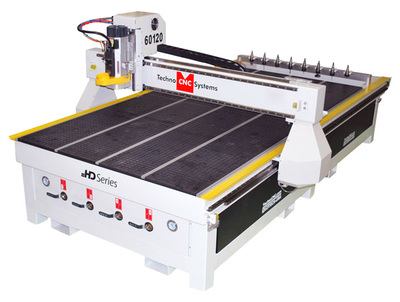

Additive Manufacturing Additive manufacturing is another term for 3D printing, and can use a variety of materials and printers. 3D printing has always been very useful for rapid prototype development, but it is starting to make its impact on the manufacturing world as well. Materials such as PLA and ABS plastics, as well as composite and metal materials improve printing. 3D printing is used as a step in the design process in companies ranging from Nike to Ford. Designers will print a prototype and use a 3D rendering to test and develop and enhance in a way that drawings can’t duplicate. Prints are faster and cheaper to produce than traditional machine tooling. The precise dimensions (often printed in color) provide a realistic model for designers and engineers to manipulate. Subtractive Manufacturing Subtractive manufacturing is a process by which 3D objects are constructed by successively cutting material away from a solid block of material. Subtractive manufacturing can be done by manually cutting the material but is most typically done with a CNC Machine. One of the advantages of subtractive manufacturing is the variety of materials that can be used, from wood and metal to plastics and acrylics to plasma. (Finer applications such as laser engravers work with an even wider array of materials.) CNC is widely used in manufacturing, and can be found in most facilities. Necessary Skill Set There is ongoing conversation about which method is more prevalent in the future of manufacturing. In reality, both have a place in 21st century manufacturing, which is why your students should be familiar with both technologies. In order for someone to comfortably use either technology, they need a solid understanding of design and CAD (Computer Aided Drafting) programs, as well as a familiarity with engineering principles so they can understand and develop using the best materials for the project. CNC operators should have a mechanical aptitude, and be able to read blueprints and drawings. Learn More You can give students hands on experience with both additive manufacturing (3D printing) and subtractive manufacturing (CNC). Moss partners with the following companies to provide cost-effective classroom solutions:

0 Comments

Leave a Reply. |

AuthorYou have questions about STEM education? You're not alone! We're here to share ideas and provide thought-provoking commentary. Let us know your thoughts! Sign Up for Email Updates For Email Marketing you can trust. Categories

All

Archives

February 2017

|

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Training Equipment

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Training Equipment

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

RSS Feed

RSS Feed