It’s 2015 – the “future” that Back to the Future dreamed about almost 30 years ago. While we don’t have hover boards or self-lacing tennis shoes, we have made some important advances – especially in the classroom. No class has changed more over the last 30 years than Career and Technical Education. In 1985, Career and Technical Education would have been known as “wood shop” or “metals” or “shop class.” In 2015, CTE classrooms have taken a decidedly different spin – and are a vital part of today’s education. So, what will CTE education look like in the next 30 years? Emphasis on Technology In the next 30 years, CTE will rely more heavily on technology – whether computer coding, robotics, or drafting work, technology will play a significant role in technical education. Hands on will always be important, but the way we deliver hands on education are changing today. In 30 years, we will rely more on 3D virtual reality for our education, where students will be able to learn a wider variety of subjects with a single piece of technology. (The future is closer than we think - check out zSpace for next level technology!) New Innovation In the next 30 years, 3D printing (or additive manufacturing) will be more prominent when designing and developing new models. Students will be familiar with computer design, and have a greater understanding of how math and visual design work together in the design process. Educators will place a greater emphasis on building knowledge and skills early. In the future, math skills will not only be taught in math class, but taught in the CTE wing as well. As a result, students will have a greater understanding of the hands on applications of math (and other STEM subjects). A Greater Umbrella Gone are the days when “CTE” refers only to wood shop. As Career and Technical Education transforms, so do the classes in the CTE wing: CTE can refer to computer programming, to welding, to Business and Marketing, Family and Consumer Science, or Renewable Energy education. In the future, CTE will take on a greater emphasis in career planning and education, making education more customized and efficient for all students. Many schools are already encouraging students to take classes in the CTE wing because it encourages K-12 students to prepare for careers after high school. Through the Test of Time Some technologies are tried and true – and the skills will always be relevant. Skills like welding, laser cutting and engraving, and industrial certification training will stand the test of time. These skills will remain relevant, even though techniques will evolve as the need for these skills changes. Do you need help bringing your CTE programs into the future? Are you looking for ideas to bring your current program into the 21st Century? Our Secondary Education Specialist is here to help – Contact Dan Sorenson for tools and ideas.

0 Comments

Your students have something to say about the direction their education is taking. Believe it – more students are taking an active role in crafting the direction of their training opportunities. Your students want to tell you a few things about the curriculum you choose. In this fast-paced, high-tech, consumer-driven world, students want to know that what they are learning today will be relevant in the real world. They also care about HOW they learn, and how you could make it better for them. (Here’s a hint: they prefer simulators in most situations!) Here are the top six things they have to say: “We learn just as effectively on a simulator as we do on the real thing.” Many educators worry that simulators aren’t life-like, and won’t provide adequate training for real situations. However, simulators have taken a page from the gaming industry and have built better graphics into modern-day simulators, making the simulations more true and engaging than ever before. Need proof? Check out the simulation on SimLog’s Forklift series here. “We need your feedback more than ever.” Whether you are using a welding simulator, a heavy equipment simulator, or something to teach pneumatics, simulation can play a key role in the education process. As an educator, you can identify specific opportunities for improvement at the spot where the student missed the target. Often, you can download a record of the simulation and coach directly to a student’s need. “We will be more engaged with the use of technology.” Integrating technology into the classroom drives engagement. Students today have grown up with laptops, smart phones, and mobile devices. They learn through the use of technology – classrooms are adapting to suit the way students learn benefits the student’s final outcomes. “The same tool can be used with multiple students.” Every educator is looking for a cost-effective way to replicate the same education from student to student. Furnishing each student with one-and-done supplies gets costly, and takes up storage space that a lot of schools don’t have. Tools like zSpace and CyberScience allow you to replicate the same dissection for multiple students – without sourcing dissection materials for each student. “We still get the hands on experience.” Many schools are afraid that the hands on experience will be lost with simulation software. However, the opposite is the case – when a school uses simulation software to teach the fundamentals, they can provide a much more meaningful experience for students who pursue advanced coursework. “We get it – budgets are tight.” Simulators are cost-effective – meaning that they can produce results with a much price tag. Students pursuing a variety of subject matters, though, can benefit from cost-effective simulation. From science to heavy machinery, there are simulators appropriate for the inquiring student, and can positively affect student outcomes. Simulators provide a more cost-effective, more sustainable alternative to the old methods. Ready to investigate? Check out Moss' cost-effective simulation options: Have you used simulation in your classroom? Tell us about it in the comments section!

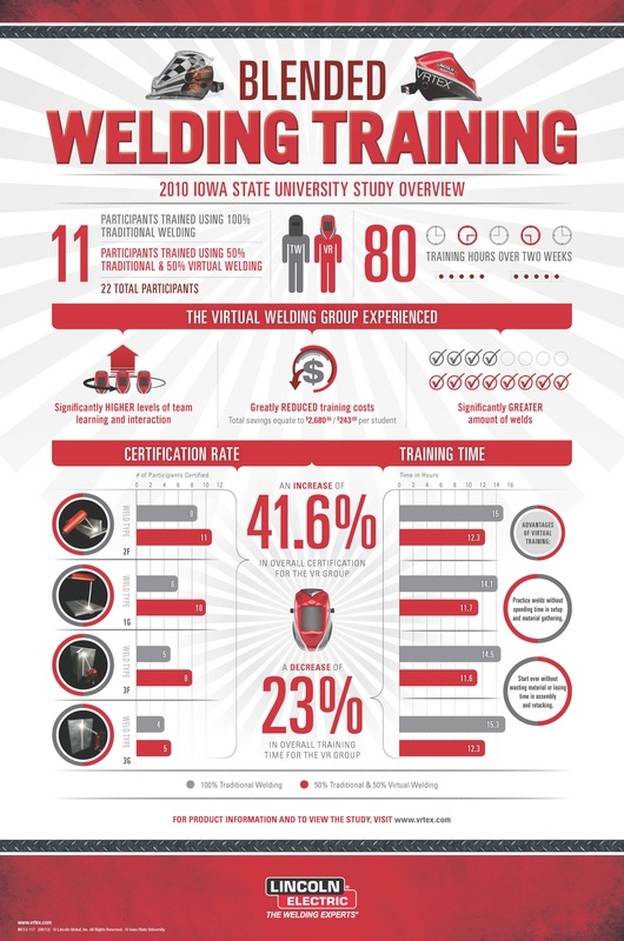

Entering its second century, the welding profession is maturing, with many employers requiring more exposure to robotic automation, advanced equipment, exotic materials, specialized code certification, theory, welding procedure specifications and more. With advances and specialization, there is a growing need for welders who understand more than how to hold a torch and join metal. As a result, public, private and skilled trade schools at every level are developing new education programs to designed to deliver the workforce industry is demanding today to remain globally competitive. In parallel, the need for skilled welding instructors and appropriate curriculum is growing as workforce development partnerships take hold and federal and state grant funds become available. 7 Essential Components of a Successful Welding Program 1. Curriculum – A well-designed welding program will include curriculum that covers technique, industry trends, and introductions to the different areas of welding. 2. Training Equipment – welding is a hands-on course, so real world training opportunities are a must. Training equipment should include an introduction to ARC welding, TIG welding, MIG welding, and FCAW welding. 3. Welding Safety -- For an ARC welder, safety practices and personal protective equipment, when used properly, protect against potential hazards. A robust training program will inform and remind students about safe shop welding practices. 4. Hands-On Practice – Many welding programs teach with a mix of virtual and hands-on training. Welding simulators, like the RealWeld Trainer will teach essential skills in a controlled environment, while Robotic Education Cell 2.0 will educate students on robotics in welding. 5. Apprenticeship Opportunities – Different techniques widely vary in the field. Pairing an inexperienced welder with a more seasoned professional will allow students to gain industry knowledge while working toward certification. Apprenticeships often set up long-standing mentor relationships. 6. Certification – industry recognized credentials, like certifications offered by Lincoln Electric, will add credibility to students as they enter the workforce. 7. Career Connections – According to Chron, welders have a strong career outlook in the coming years, anticipating 15% growth in the field. Welding programs should have strong ties to the local workforce and supply a steady stream of qualified labor to local employers. Welding programs are a significant part of Career and Technical Education. Need help assessing your program? Contact Moss for a free consultation or to set up a live demonstration*.

*Demonstrations available in Iowa, Illinois, Nebraska and South Dakota. |

AuthorYou have questions about STEM education? You're not alone! We're here to share ideas and provide thought-provoking commentary. Let us know your thoughts! Sign Up for Email Updates For Email Marketing you can trust. Categories

All

Archives

February 2017

|

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- APT Manufacturing

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Equipment

- FANUC-Robotics & CNC

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- Levil Technology-CNC

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

- Home

-

K-12

- College

- Industry

- Certifications

-

Partners

- Afinia-3D Printing

- Amatrol-Manufacturing Training Equipment

- Apolo Studios- Welding Simulation

- APT Manufacturing

- Bantam Tools - CNC

- CEF-Custom Educational Furniture

- DAC Worldwide-Manufacturing Equipment

- FANUC-Robotics & CNC

- Greene Manufacturing Inc - Furniture

- Iconic CNC

- Interior Concepts-Furniture

- Levil Technology-CNC

- MSSC Certifications

- MINDS-i Education

- Pitsco Education-STEM

- SimLog-Heavy Equipment Simulation

- Stokes Robotics

- Techno CNC Systems

- Universal Laser Systems

- VictoryXR - Virtual Reality

- WB Mfg - Furniture

- Funding

- Contact

- About

RSS Feed

RSS Feed